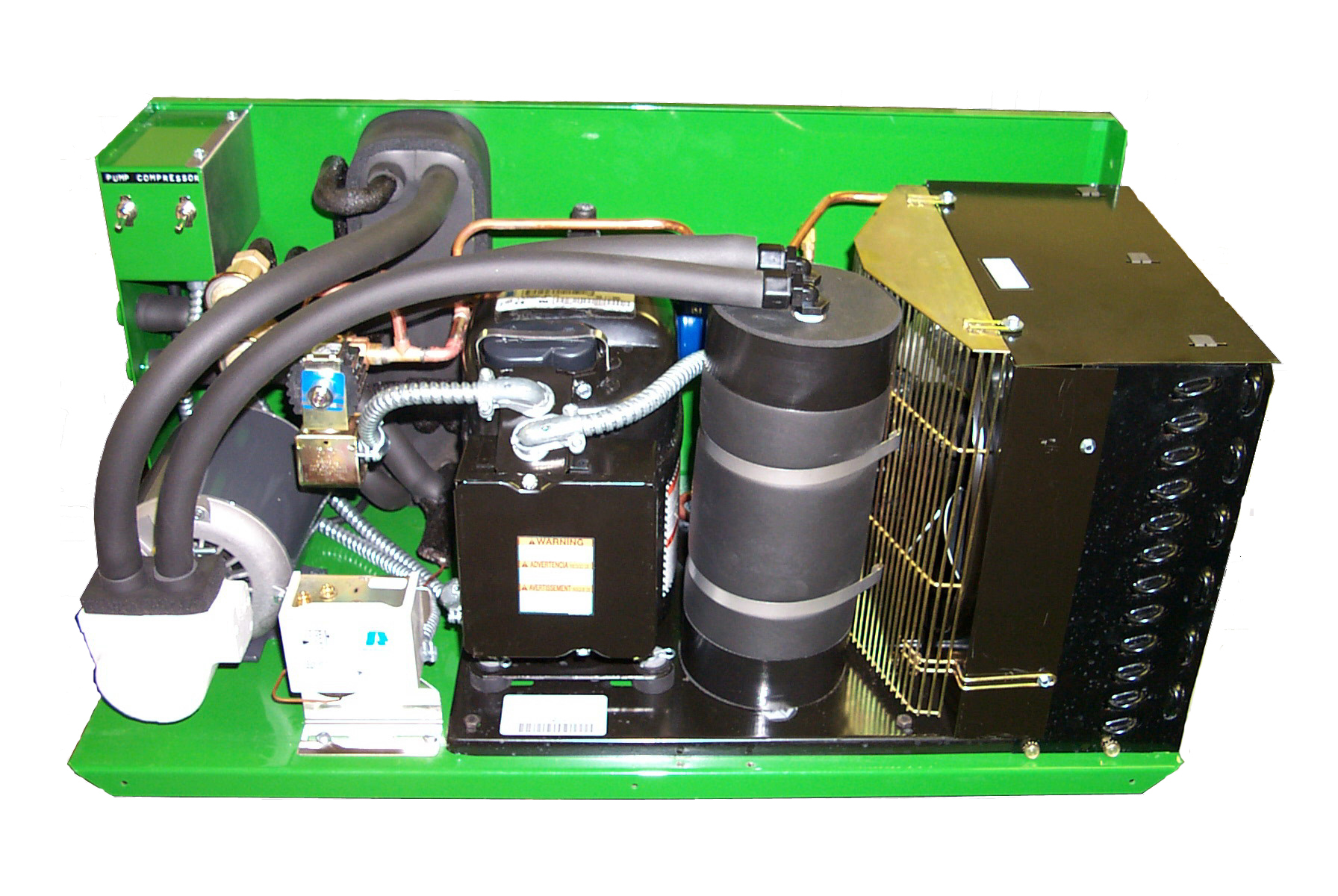

WATER CHILLERS

With Perfection, colder water does mean more ice

Heat and ice don’t mix. That’s certainly no secret. High temperatures in commercial kitchens and hot incoming water supply can negatively impact your ice machine’s production. Without a Perfection RA-34 Potable Water PreChiller, you are at the mercy of these variables.

But by adding a Perfection RA-34 Water Chiller, with its unique Ultra Chill recirculating system, you can be assured of optimum production from your ice machine.

With Perfection’s RA-34 Water Chiller, water is maintained at a constant temperature (+ 1/8 of a degree Fahrenheit), giving you the maximum performance from your ice machines.

Major ice machine manufacturers clearly state in their literature that colder water means more ice. Their specification sheets show that reducing incoming water supply from 90F to 50F will result in more ice.

Other uses for our water chillers:

* Soda dispensing

* Juice dispensing

* Bakery applications

WATER CHILLER CUT SHEETS